The Hidden World of Automotive Microfactories

Imagine walking into a facility no larger than a typical warehouse, yet witnessing the birth of fully-functional, road-ready vehicles. Welcome to the world of automotive microfactories, a revolutionary approach to car manufacturing that's reshaping the industry landscape. This innovative concept is challenging traditional production methods and opening doors to unprecedented customization and efficiency.

The Genesis of Automotive Microfactories

The concept of microfactories in the automotive sector isn’t entirely new, but it has gained significant traction in recent years. Rooted in the principles of lean manufacturing and just-in-time production, microfactories represent a shift away from the massive, centralized production facilities that have dominated the industry for decades.

The idea was first popularized in the 1990s by Japanese researchers looking to create more efficient and environmentally friendly manufacturing processes. However, it wasn’t until the late 2000s and early 2010s that the concept began to gain serious attention in the automotive world, driven by advancements in robotics, 3D printing, and digital manufacturing technologies.

The Anatomy of an Automotive Microfactory

At its core, an automotive microfactory is a small-scale, highly automated production facility capable of producing complete vehicles or major components. Unlike traditional car plants that can span millions of square feet, microfactories typically occupy spaces of 50,000 to 200,000 square feet – about the size of a large supermarket.

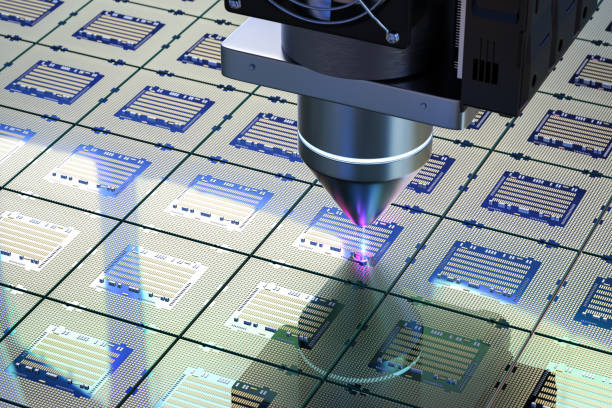

These facilities leverage cutting-edge technologies such as advanced robotics, artificial intelligence, and additive manufacturing to create a flexible and efficient production environment. The key to their success lies in their modular design, which allows for rapid reconfiguration to accommodate different vehicle models or production needs.

The Benefits of Thinking Small

Microfactories offer numerous advantages over traditional automotive manufacturing methods. Perhaps the most significant is their ability to drastically reduce the capital investment required to start vehicle production. This lower barrier to entry is enabling new players to enter the market, fostering innovation and competition.

Furthermore, the compact nature of microfactories allows them to be located closer to end markets, reducing transportation costs and environmental impact. Their flexibility also enables quicker response to market demands, allowing for more customized and limited-run vehicle production that would be economically unfeasible in larger plants.

Challenges and Limitations

Despite their potential, microfactories face several challenges. Scale remains a significant hurdle – while perfect for niche or luxury vehicles, microfactories struggle to match the output of traditional plants for mass-market models. There are also concerns about the quality and consistency of vehicles produced in these smaller facilities, although proponents argue that advanced quality control systems can mitigate these issues.

Another challenge lies in the supply chain. Traditional automotive supply chains are optimized for large-scale production, and adapting them to the needs of microfactories requires significant restructuring. However, as the concept gains traction, new supply chain models are emerging to support this more distributed manufacturing approach.

The Future of Car Manufacturing

As we look to the future, it’s clear that microfactories will play an increasingly important role in the automotive landscape. While they’re unlikely to completely replace traditional manufacturing methods, they represent a complementary approach that could reshape significant portions of the industry.

We’re already seeing major automakers experiment with microfactory concepts, particularly for electric vehicles and specialized models. Startups, too, are leveraging this approach to bring innovative designs to market without the need for massive capital investments.

Moreover, the principles behind microfactories are influencing larger manufacturing operations, leading to more flexible and efficient production lines even in traditional plants. This cross-pollination of ideas is driving a broader transformation in how we think about and approach vehicle manufacturing.

Implications for the Automotive Ecosystem

The rise of microfactories has far-reaching implications for the entire automotive ecosystem. For consumers, it could mean greater access to customized vehicles and potentially lower prices due to reduced manufacturing and transportation costs. For the industry, it opens up new possibilities for market entry and innovation, potentially leading to a more diverse and dynamic automotive landscape.

From an environmental perspective, microfactories offer the potential for more sustainable manufacturing practices. Their smaller footprint, reduced energy consumption, and ability to locate closer to end markets all contribute to a lower carbon footprint compared to traditional manufacturing methods.

A New Chapter in Automotive History

As we stand on the cusp of a new era in automotive manufacturing, microfactories represent one of the most exciting developments in decades. They embody a shift towards more agile, responsive, and localized production methods that could fundamentally alter the way we think about car manufacturing.

While challenges remain, the potential benefits of this approach are too significant to ignore. As technology continues to advance and the automotive industry grapples with the need for greater flexibility and sustainability, microfactories are poised to play an increasingly important role in shaping the future of how we build and consume vehicles.

The automotive microfactory revolution is just beginning, and its full impact is yet to be realized. But one thing is clear – the days of thinking that bigger is always better in car manufacturing are over. The future may well belong to those who can think small, act fast, and adapt quickly in the ever-evolving world of automotive production.