Mastering Modular Production: A Blueprint for Agile Manufacturing

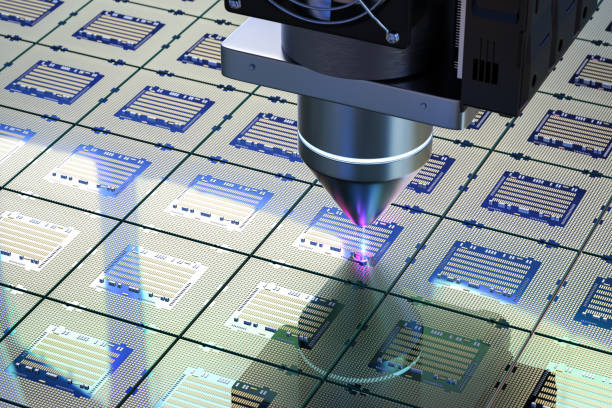

In today's rapidly evolving industrial landscape, agility and adaptability are paramount. Modular production systems have emerged as a game-changing approach, offering manufacturers unprecedented flexibility and efficiency. This innovative methodology reimagines traditional production lines, breaking them down into interchangeable, self-contained units that can be quickly reconfigured to meet changing market demands. As we delve into the world of modular production, we'll explore its transformative potential and how it's reshaping the future of manufacturing.

In traditional manufacturing setups, production lines are often rigid and specialized, designed to produce specific products at high volumes. While efficient for mass production, these systems struggle to adapt to changing consumer preferences or market fluctuations. Modular production addresses this limitation by breaking down the manufacturing process into discrete, standardized units that can be easily rearranged or replaced.

The Anatomy of a Modular Production System

At its core, a modular production system consists of several key components:

-

Standardized Modules: These are self-contained units that perform specific functions within the production process. Each module is designed to be plug-and-play, allowing for easy integration and reconfiguration.

-

Flexible Infrastructure: The physical layout of the factory floor is designed to accommodate frequent changes, with movable equipment and adaptable utility connections.

-

Intelligent Control Systems: Advanced software and control systems orchestrate the interactions between modules, optimizing workflow and managing production schedules.

-

Standardized Interfaces: Common interfaces ensure seamless communication and integration between different modules, regardless of their manufacturer or specific function.

-

Scalable Design: The system is inherently scalable, allowing manufacturers to add or remove modules as needed to adjust production capacity.

Advantages of Embracing Modular Production

The benefits of adopting a modular production approach are numerous and significant:

-

Enhanced Flexibility: Manufacturers can quickly adapt to market changes by reconfiguring their production lines, enabling rapid product changeovers and the introduction of new products.

-

Improved Efficiency: By optimizing each module independently and as part of the whole system, overall production efficiency can be significantly increased.

-

Reduced Downtime: When a module requires maintenance or upgrades, it can be swapped out without shutting down the entire production line.

-

Cost-Effective Scaling: Companies can scale their production capacity incrementally by adding new modules, rather than investing in entirely new production lines.

-

Easier Integration of New Technologies: As new technologies emerge, they can be incorporated into the production process by simply adding or upgrading specific modules.

Implementing Modular Production: Challenges and Solutions

While the benefits of modular production are clear, implementation can present several challenges:

-

Initial Investment: The upfront cost of transitioning to a modular system can be substantial. However, the long-term benefits often outweigh these initial expenses.

-

Standardization: Developing standardized interfaces and protocols across different modules and suppliers can be complex. Industry collaboration and the adoption of common standards are crucial to overcoming this hurdle.

-

Workforce Adaptation: Employees need to be trained to work with modular systems, which may require a different skill set compared to traditional production methods.

-

System Complexity: Managing a highly flexible and interconnected system requires sophisticated control systems and expertise.

To address these challenges, companies are investing in comprehensive training programs, collaborating with technology partners, and adopting phased implementation approaches to manage costs and complexity.

Real-World Success Stories

Several leading manufacturers have already embraced modular production with impressive results:

-

A major automotive manufacturer implemented a modular assembly line that reduced product changeover time by 50% and increased overall production flexibility by 30%.

-

A consumer electronics company adopted a modular approach for its smartphone production, enabling it to introduce new models 25% faster than its competitors.

-

A pharmaceutical firm used modular production units to quickly scale up vaccine production during a global health crisis, demonstrating the agility of this approach in critical situations.

Key Strategies for Successful Modular Production Implementation

• Start with a pilot project to test and refine the modular approach before full-scale implementation

• Invest in comprehensive employee training programs to ensure a smooth transition

• Collaborate with suppliers and industry partners to develop standardized interfaces and protocols

• Implement advanced analytics and AI-driven control systems to optimize module interactions and overall efficiency

• Regularly reassess and update your modular strategy to align with evolving market demands and technological advancements

As we look to the future of manufacturing, modular production stands out as a pivotal innovation that enables unprecedented agility and efficiency. By breaking down traditional production barriers and embracing a more flexible, adaptable approach, manufacturers can position themselves to thrive in an increasingly dynamic and competitive global marketplace. The journey towards modular production may be challenging, but for those who successfully navigate this transition, the rewards in terms of improved efficiency, adaptability, and market responsiveness are substantial. As industry leaders continue to innovate and refine this approach, modular production is set to play a central role in shaping the factories of tomorrow.