Sustainable Practices in Modern Manufacturing

Modern manufacturing faces an evolving landscape where efficiency and profitability must increasingly align with environmental responsibility. Sustainable practices are no longer optional but are becoming integral to long-term success and resilience within the industrial sector. This shift reflects a growing awareness of ecological impacts, resource depletion, and the demand for more responsible production methods across global supply chains. Embracing sustainability offers numerous benefits, from reduced operational costs to enhanced brand reputation and compliance with international regulations.

The Role of Sustainability in Modern Industrial Operations

Sustainability in modern industrial operations involves a holistic approach to minimizing environmental impact while ensuring economic viability. This goes beyond mere compliance, embedding eco-friendly principles into the core of manufacturing processes. Enterprises are increasingly adopting strategies that consider the entire lifecycle of a product, from raw material extraction to disposal. This comprehensive view helps identify areas for significant improvement in resource use, waste reduction, and emissions control, driving a more responsible form of industrial development.

Integrating Sustainable Production and Supply Chain Strategies

Effective sustainable production requires a re-evaluation of the entire supply chain. From sourcing raw materials responsibly to optimizing logistics and distribution, every stage presents an opportunity for greater environmental stewardship. Companies are implementing strategies such as local sourcing to reduce transportation emissions, using recycled or renewable materials, and designing products for durability and recyclability. This integration across the supply chain enhances overall efficiency and reduces the ecological footprint associated with commerce and global trade.

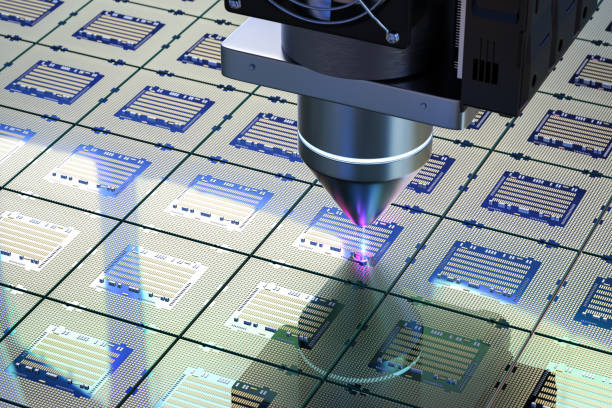

Technological Innovation for Environmental Efficiency

Technological innovation is a critical driver for achieving environmental efficiency in manufacturing. Advanced technologies, such as artificial intelligence, IoT, and big data analytics, enable precise monitoring and optimization of production processes, minimizing waste and energy consumption. The development of new materials, like biodegradable plastics or lightweight composites, also contributes significantly to reducing environmental impact. These innovations are essential for fostering a more sustainable economy and driving progress in green industrial practices.

Automation’s Contribution to Sustainable Manufacturing

Automation plays a pivotal role in advancing sustainable manufacturing. Automated systems can precisely control processes, reducing errors, material waste, and energy use. For instance, robotic systems can optimize material handling and assembly, leading to fewer defects and less scrap. Furthermore, automation can facilitate the adoption of lights-out manufacturing, where facilities operate with minimal human intervention, often leading to lower energy consumption for lighting, heating, and cooling. This focus on efficiency through automation supports the broader goals of sustainability and responsible operations.

Economic Benefits and Global Market Impact of Green Practices

Adopting green practices offers substantial economic benefits beyond environmental protection. Reduced energy consumption, waste minimization, and efficient resource use directly translate into lower operational costs. Moreover, a commitment to sustainability can enhance brand reputation, attract environmentally conscious consumers, and open new global market opportunities. Many governments and international bodies offer incentives for sustainable enterprises, further bolstering their competitive edge. This strategic approach aligns business growth with ecological responsibility, contributing positively to the broader economy and international trade relations.

Workforce Engagement and Enterprise Development for a Sustainable Future

Cultivating a culture of sustainability within an enterprise requires significant workforce engagement and ongoing development. Training programs can educate employees on sustainable practices, waste reduction, and energy conservation. Empowering the workforce to identify and implement eco-friendly solutions fosters a sense of ownership and drives continuous improvement. Leadership commitment to sustainable strategy is also crucial, guiding the entire organization towards greener operations and ensuring that sustainability is integrated into long-term business development plans. This collective effort is vital for the successful transition to a more sustainable industrial future.

Sustainable practices in modern manufacturing represent a fundamental shift towards more responsible and resilient industrial operations. By integrating sustainability into every aspect, from production and supply chain management to technological innovation and workforce engagement, businesses can achieve both environmental stewardship and economic prosperity. This comprehensive approach is essential for navigating the complexities of the global market and ensuring long-term viability for enterprises worldwide.