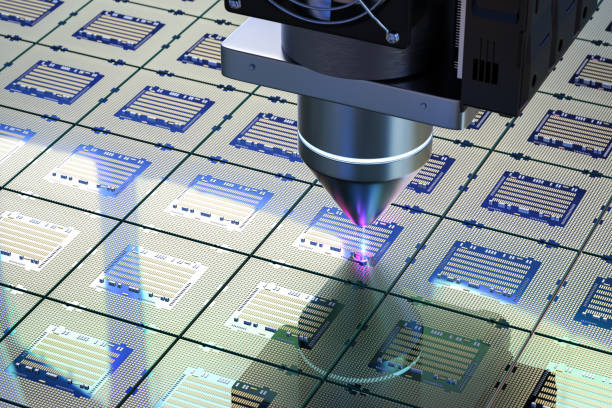

Advanced Robotics Reshaping Manufacturing Landscapes

The manufacturing sector is undergoing a profound transformation driven by the integration of advanced robotics. These sophisticated machines are moving beyond simple repetitive tasks, now performing complex operations with precision and adaptability. This evolution is not merely about automation but represents a fundamental shift in how goods are produced, distributed, and managed across global supply chains, promising increased efficiency and new opportunities for innovation within the industry.

How are Advanced Robotics Driving Manufacturing Innovation?

Advanced robotics are at the forefront of a new era in manufacturing, characterized by unprecedented levels of precision, speed, and flexibility. These robotic systems, often integrated with artificial intelligence and machine learning, can perform intricate tasks that were previously only possible for highly skilled human workers. From collaborative robots (cobots) working alongside humans to fully autonomous mobile robots navigating factory floors, the technology is enabling manufacturers to innovate production processes, develop new products faster, and respond dynamically to market demands. This technological leap fosters an environment where innovation is not just supported but actively propelled by intelligent automation.

Enhancing Production Efficiency and Operations Through Digitization

The integration of advanced robotics is intrinsically linked to the broader trend of digitization in manufacturing. By connecting robots to a centralized digital ecosystem, manufacturers can monitor operations in real-time, collect vast amounts of data, and use analytics to optimize every stage of production. This digitization allows for predictive maintenance, reducing downtime and extending the lifespan of machinery. It also enables highly flexible production lines that can quickly reconfigure for different product variants or entirely new products, leading to significant enhancements in overall operational efficiency and output quality. The precision offered by robotics minimizes waste, contributing to more sustainable production practices.

Transforming Supply Chain and Logistics Management

Robotics are playing a crucial role in revolutionizing supply chain and logistics management. Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) are streamlining the movement of materials within factories and warehouses, reducing manual labor and improving accuracy in inventory management. In logistics, robotic sorting systems and automated storage and retrieval systems (AS/RS) accelerate order fulfillment and optimize storage space. These advancements contribute to a more resilient and responsive supply chain, crucial for navigating the complexities of global trade. By automating these processes, companies can achieve faster delivery times, reduce operational costs, and enhance the overall customer experience.

Impact on the Workforce and Future Economic Landscape

The widespread adoption of advanced robotics is reshaping the manufacturing workforce. While some roles may be automated, there is a growing demand for new skills in areas such as robot programming, maintenance, data analytics, and system integration. This shift necessitates investment in training and upskilling programs to prepare the workforce for the jobs of tomorrow. From an economic perspective, enhanced productivity and efficiency driven by robotics can lead to increased competitiveness for enterprises on a global scale. This can stimulate economic growth, attract investment, and foster the development of new industries and services that support the robotic ecosystem. Sustainability also benefits as optimized processes reduce energy consumption and material waste.

Cost Considerations for Robotics Implementation

Implementing advanced robotics in manufacturing involves various cost factors, including the initial purchase of robots, software, integration services, training, and ongoing maintenance. The return on investment often comes from increased production efficiency, reduced labor costs, improved product quality, and enhanced safety. While the upfront investment can be substantial, the long-term benefits in terms of operational savings and competitive advantage are often compelling. Companies typically evaluate the total cost of ownership (TCO) over the lifespan of the robotic system, considering factors like energy consumption, spare parts, and potential upgrades. The specific cost will vary significantly based on the type of robot, its payload capacity, reach, precision, and the complexity of the tasks it is designed to perform.

| Product/Service | Provider | Cost Estimation |

|---|---|---|

| Collaborative Robot | Universal Robots | $25,000 - $50,000 |

| Industrial Robot Arm | FANUC America | $30,000 - $100,000+ |

| Autonomous Mobile Robot | Locus Robotics | $40,000 - $70,000 |

| Robot Integration Services | JR Automation | Project-based (variable) |

| Robot Programming Software | ABB Robotics | $5,000 - $20,000 (per license) |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

In conclusion, advanced robotics are not just a technological upgrade but a strategic imperative for modern manufacturing. Their ability to enhance efficiency, drive innovation, streamline supply chains, and adapt to evolving market demands positions them as a critical component in the future of industry. As these technologies continue to mature and become more accessible, their influence will undoubtedly expand, further shaping the global economy and the nature of work.