Adaptive Production Systems: Revolutionizing Manufacturing Flexibility

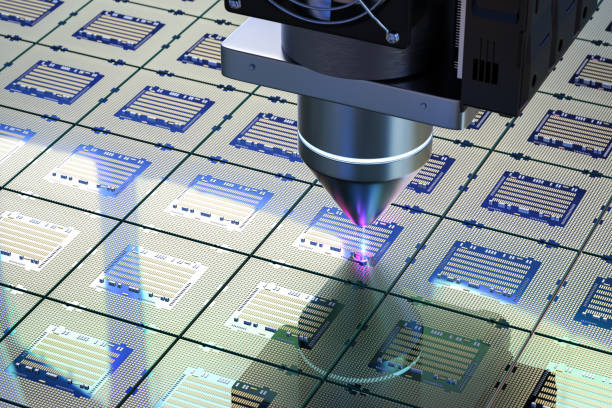

The manufacturing landscape is undergoing a seismic shift as companies grapple with increasingly volatile markets and unpredictable consumer demands. Adaptive Production Systems (APS) have emerged as a game-changing solution, offering unprecedented levels of flexibility and responsiveness in manufacturing processes. This innovative approach is reshaping how industries conceptualize and implement their production strategies, promising to redefine competitive advantage in the years to come.

Core Components of APS

At the heart of Adaptive Production Systems lies a network of interconnected, intelligent components. These include:

-

Modular Production Units: Easily reconfigurable equipment that can be quickly adapted for different production needs.

-

Real-time Data Analytics: Advanced sensors and analytics tools that provide instant insights into production processes.

-

Artificial Intelligence and Machine Learning: Algorithms that optimize production schedules and predict maintenance needs.

-

Collaborative Robots (Cobots): Flexible robotic systems that can work alongside human operators and adapt to new tasks rapidly.

-

Digital Twin Technology: Virtual replicas of physical production systems that enable simulation and optimization of processes.

The Tangible Benefits of APS Implementation

Companies that have successfully implemented Adaptive Production Systems report significant improvements across various metrics. A study by the Manufacturing Institute revealed that APS adopters experienced an average of 30% reduction in changeover times and a 25% increase in overall equipment effectiveness (OEE). Furthermore, these systems have shown to reduce time-to-market for new products by up to 50%, giving companies a crucial edge in fast-paced industries.

Challenges in Adopting APS

While the benefits of Adaptive Production Systems are clear, implementation is not without its challenges. One of the primary hurdles is the substantial initial investment required. The cost of upgrading existing infrastructure and retraining personnel can be prohibitive for some organizations. Additionally, there’s a significant learning curve associated with managing these complex systems, often requiring a cultural shift within the organization towards more data-driven decision-making processes.

Future Trajectories: Where APS is Heading

The future of Adaptive Production Systems looks promising, with several exciting developments on the horizon. Experts predict a move towards even more autonomous systems, where AI-driven decision-making will play an increasingly central role. There’s also a growing interest in incorporating augmented reality (AR) into APS, allowing for enhanced operator guidance and remote expert assistance. As these technologies mature, we can expect to see APS becoming more accessible to small and medium-sized enterprises, potentially democratizing advanced manufacturing capabilities.

Implementing APS: Key Considerations for Success

• Conduct a thorough assessment of current production processes to identify areas ripe for adaptation.

• Invest in comprehensive training programs to ensure staff are equipped to operate new systems effectively.

• Start with pilot projects in specific production areas before rolling out APS across the entire facility.

• Prioritize cybersecurity measures to protect the interconnected nature of APS from potential threats.

• Develop a clear roadmap for scaling APS implementation, considering both short-term wins and long-term goals.

In conclusion, Adaptive Production Systems represent a transformative approach to manufacturing that aligns perfectly with the demands of today’s dynamic market environment. By embracing this technology, companies can position themselves at the forefront of innovation, ready to meet whatever challenges the future may hold. As the manufacturing sector continues to evolve, those who successfully implement APS will likely find themselves with a significant competitive advantage, capable of responding to market changes with unprecedented speed and efficiency.